Friday, 23 January 2015

Thursday, 22 January 2015

steel reinforcement for home builders

1. What is steel reinforcement? Why is it required in a concrete structure?

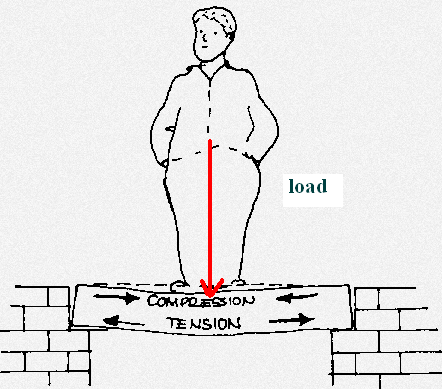

Concrete is

a material that is very strong in compression, but weak in tension. To

compensate for this imbalance in a concrete slab behavior, steel reinforcement

bar is cast into it to carry the tensile loads. The surface of the

reinforcement bar may be patterned to form a better bond with the concrete. Steel

should necessarily be strong in tension and, at the same time, be ductile

enough to be shaped or bent. Steel rebar is most commonly used as a tensioning

devise to reinforce concrete to help hold the concrete in a compressed state.

To achieve this aim, the designer needs to determine, not only the amount of reinforcement to be used, but how it is to be distributed and where it is to be positioned. These decisions of the designer are critical to the successful performance of reinforced concrete and it is imperative that, during construction, reinforcement be positioned exactly as specified by the designer.

Steel rebars can take both tensile as well as compressive loads. Steel & concrete have got similar temperature coefficients, making them expand/contract together and help the bonding.

The welding of reinforcement is generally not permitted for high tensile steel, since heating of hot rolled bars causes brittle fracture in the reinforcement. In the case of cold worked deformed (CTD) steel bars, heating causes the reinforcement to revert to mild steel as it loses the effects of strain hardening. Welding is normally permitted on mild steel and in some cases quenched and self tempered steel rebars.

2. What are the different grades of reinforcement

steel available?

Mild steel bars

conforming to IS: 432 (Part I) and Cold-worked steel high strength deformed

bars conforming to IS: 1786 (grade Fe 415 and grade Fe 500, where 415 and 500

indicate yield stresses 415 N/mm2 and 500 N/mm2 respectively) are commonly

used. Grade Fe 415 is being used most commonly nowadays. This has limited the

use of plain mild steel bars because of higher yield stress and bond strength

resulting in saving of steel quantity.

Fe 500 D, Fe 550D (where D denotes ductile) and Fe600 grade in normal, EQR (Earthquake Resistant) & CRS (Corrosion Resistant) quality.

Fe 500 D, Fe 550D (where D denotes ductile) and Fe600 grade in normal, EQR (Earthquake Resistant) & CRS (Corrosion Resistant) quality.

- What is TMT bar? What is the difference between TMT, Tempcore and Thermex reinforcement bars?

Thermo Mechanical

Processing, also known as Thermo-Mechanical Treatment (TMT), is a metallurgical

process that integrates work hardening and heat treatment into a single process.

Thermex and Tempcore

are both reputed trade names registered by the two major providers of TMT

technology. When properly operated both Thermex and Tempcore can produce good

quality TMT rebars. Both are highly complex technologies involving specialized

computerized equipments to control and produce desired grade and quality of

steel.

Manufacture of high strength reinforcing steel is usually carried out through one of three alternative process routes:

1. Hot rolling after micro-alloying

2. Hot rolling followed by cold work and

3. Hot rolling followed by heat treatment (TMT).

Manufacture of high strength reinforcing steel is usually carried out through one of three alternative process routes:

1. Hot rolling after micro-alloying

2. Hot rolling followed by cold work and

3. Hot rolling followed by heat treatment (TMT).

The TMT process is actually a heat treatment imparted to steel on-line just after rolling.

4. What are the different sizes of TMT

available?

Normally TMT is available in 6-50 (mm) (6,8,10,12,16,20,25,28,32,36,40,45,50),

where 6-12 mm is available in coil as well as straight form .Cold-worked steel

high strength deformed bars start from 8 mm diameter. For general house

constructions, bars of diameter 6 to 20 mm are used.

5. Quality factors to be cheked during

purchase of steel reinforcement:

- Weight/unit length: TMT Rebars should have standard weights, lengths as mentioned in the standards (IS 1786).

- Bond Strength: TMT Rebars should have uniform and precise parallel rib pattern, which ensures excellent bonding with concrete, and provides superior strength to the buildings.

- Dimensions: Rebars should have close dimensional tolerance and superior surface finish,

- Bendability: Rebars must have high elongation so that they are capable of absorbing large amount of energy by plastic deformation before undergoing failure by fracture. This facilitates easy bending, making work easier and faster at construction sites.

- Weld-ability: TMT Rebars should have low carbon equivalent which is directly related to hydrogen induced cold cracking (the most common weld defect for steel). Higher concentration of carbon and other alloying element tend to increase hardness and decrease weld-ability. TMT process can produce the desired yield strength with steel of relatively lower carbon equivalent by adjusting the on-line heat treatment parameters. Low level of carbon content leading to excellent weldability.

- Corrosion Resistant: TMT Rebars should have minimum or negligible residual stresses in order to prevent any chance of rusting.

- Earthquake Resistance: TMT Rebars having high UTS/YS ratio signifies that steel is capable of elongating to a large extent when loaded beyond yield point as in the situation of an earthquake. It is with this view that some of the international specifications stipulate fairly high values for the UTS / YS ratio

- Durability & Strength: TMT Rebars should have very low level of Sulphur (S) and Phosphorous (P) as they reduce the strength of the material and make them brittle. Excess level of S can lead to hot shortness wherein the melting point of steel gets lowered, thus making steel more prone to failure under extreme high temperature conditions. Excess level of P can lead to cold shortness wherein the steel undergoes brittle fracture while working in extremely cold condition and thus becomes more prone to cracking.

- Cost Savings: TMT Rebars having high UTS/YS ratio and high elongation results in lesser consumption of the similar TMT of the same sectional properties but with low UTS/YS ratio and lesser elongation. Usually TMT with high strength saves about 10-12% steel than corresponding lesser strength TMT.

- Manufacturing technology: TMT Rebars should be produced using the superior and clean steel billets with highly controlled steel chemistry with very low levels of sulphur and phosphorus (less than 0.035% Lower the level of sulphur and phosphorous, more is the strength of steel.), and very low levels of inclusion and tramp elements. To ensure this Check the manufacturers website to identify manufacturing process.

- Steel test certificates are issued from NABL (National Accreditation Board of Laboratories) certified Laboratory.

Physical properties of

various grades of steel reinforcement

Chemical properties of various grades of

steel reinforcement

- Corrosion resistant (CRS) Rebars:

Advantages of using CRS rebars:

- Longer Life, suited for coastal environment.

- High yield strength coupled with good ductility and bendability.

- No extra precaution required in material handling and transportation.

- No maintenance required during fabrication.

- More suitable under poor workmanship conditions at site.

- No extra precaution during welding.

- Can be bent and re-bent around very small mandrels.

- Can be used as a reinforcement material in the seismic zones.

7. What is the checklist for steel reinforcement before the placement/pour of concrete?

- Steel bars are clear, free from loose mil scales, dust and loose rust ,coats of paints, oil or other coatings which may destroy or reduce bond strength.

- Steel bars should be stored in such a way as to prevent corrosion.

- Steel bars should not be clean by oily substance to remove the rust.

- The bar is bent correctly and accurately to the size and shape as shown in drawings.

- If possible, bar of full length is used.

- Overlapping bars do not touch each other and these should be kept apart with concrete.

- The overlap if given should be staggered.

- The cranks in the bar at the end should be kept in position by using spots.

- The steel bars should not be disturbed while lying cements concrete,

- Reinforcements shall be placed and tied such that concrete placement is possible

- Without segregation, and compaction possible by an immersion vibrator.

- Required cover under steel bars should be given before laying the cement concrete

8. Why cover blocks are required to be placed before concreting? What are their sizes?

Cover blocks are placed to prevent the steel rods from getting exposed to the atmosphere, and to place and fix the reinforcements as per the design drawings. Once the steel is exposed to the atmosphere, corrosion starts. Sometimes it is commonly seen that the cover gets misplaced during the concreting activity. To prevent this, tying of cover with steel bars using thin steel wires called binding wires (projected from cover surface and placed during making or casting of cover blocks) is recommended. Covers should be made of cement sand mortar (1:3). Ideally, cover should have strength similar to the surrounding concrete, with the least perimeter so that chances of water to penetrate through periphery will be minimized. Provision of minimum covers as per the Indian standards for durability of the whole structure should be ensured.Shape of the cover blocks could be cubical or cylindrical. However, cover indicates thickness of the cover block. Normally, cubical cover blocks are used. As a thumb rule, minimum cover of 2" in footings, 1.5" in columns and 1" for other structures may be ensured.

Cover has the most significant effect on the long term durability of reinforced concrete and therefore of the structure. Excess cover should be avoided as micro cracking due to bending stress can result in the growth and development of cracks and resulting corrosion of reinforcement or member loss due to spalling. The correct cover is required to ensure that reinforced concrete members meet their specified design requirements.

9. How important are transverse reinforcements like links and stirrups? What precautions should be taken while tying them?

Transverse reinforcements are very important. They not only take care of structural requirements but also help main reinforcements to remain in desired position. They play a very significant role while abrupt changes or reversal of stresses like earthquake etc.They should be closely spaced as per the drawing and properly tied to the main/longitudinal reinforcement.

10. What is a lap or development length? Where and how should they be provided?

Lap length is the length overlap of bars tied to extend the reinforcement length.. Lap length about 50 times the diameter of the bar is considered safe. Laps of neighboring bar lengths should be staggered and should not be provided at one level/line. At one cross section, a maximum of 50% bars should be lapped.In case, required lap length is not available at junction because of space and other constraints, bars can be joined with couplers or welded (with correct choice of method of welding).

11. What is anchorage length?

This is the additional length of steel of one structure required to be inserted in other at the junction. For example, main bars of beam in column at beam column junction, column bars in footing etc. The length requirement is similar to the lap length mentioned in previous question or as per the design instructions.12. For a given diameter, how do we calculate the weight of steel per meter length of the steel bar and vice versa?

For any steel reinforcement bar, weight per running meter is equal to d2/162 Kg, where d is diameter of the bar in mm. For example, 10 mm diameter bar will weigh (10x10)/162 = 0.617 Kg/m

13. What is the Stress-Strain curve? what is the importance of YS, UTS and

Percentage Elongation?

Yield stress: Is the stress a material can withstand without permanent deformation, Yield strength is usually stated as the stress at which a permanent deformation of 0.2% of the original dimension will result, known as the 0.2% yield stress.

OR

The stress at which a non-proportional elongation equals to 0.2 % of the original gauge length takes place (where gauge length is 5.65sqrt A. where ’A’ is the cross sectional area of the test piece).

Ultimate Tensile Strength: The maximum stress a material can withstand in a tensile test.

OR

The maximum load (force) reached in a tensile test divided by the effective cross sectional area of gauge length portion of the test piece.

Percentage Elongation: When a material is tested for tensile strength it elongates a certain amount before fracture takes place. The two pieces are placed together and the amount of extension is measured against marks made before starting the test which is expressed as a percentage of the original gauge length.

contact rabishnair@yahoo.co.in

Wednesday, 21 January 2015

cement for home builders

Cement

Portland cement is called so

because when it hardens, it resembles a stone found in the quarries of Portland

in England.

The basic raw

material of making cement is limestone and clay.

1. Major Types of Cement

·

OPC- Ordinary Portland Cement

·

PPC- Pozzolana Portland Cement

·

PSC- Portland Slag Cement

OPC is further classified as 33 G, 43 G, and 53 G (where G

denotes grade) according to 28 day compressive strength of cement mortar cubes

prepared with cement and standard sand in

the ratio 1:3 , with water added , mould vibrated, cubes cured and tested as per Indian Standard. Thus 43 G means

the cement mortar cubes have 28 day compressive strength of 43 Mpa at 28 days.

PPC is produced by intergrinding predetermined quantities of

Portland cement clinker and pozzolana

(Fly ash, 15 to

35 % by weight), (Fly ash is a byproduct in coal based thermal power plants) If

strict quality control procedures are adopted at the cement plant while

selecting fly ash then PPC can generally be used wherever OPC is used under

normal circumstances.

PPC is

especially suited for mass concrete works like foundation and for structures

subjected to aggressive environments (like sewers, marine construction)

.

As per Indian Standards PPC has to satisfy the strength

requirement of 33 G OPC, but in reality higher strength PPC are available in

the market.

PSC is made by intergrinding 35 to 65 percent of OPC clinker with

Ground Granulated Blast Furnace

slag (GGBFS)

slag (GGBFS)

(an industrial waste product obtained during the

manufacture of pig iron). PSC is most suitable for construction near coastal

areas but is unsuitable in cold weather.

PSC gains

strength less rapidly than OPC, but unlike OPC it continues to gain strength significantly

even after 28 days and hence the ultimate strength gained is higher than same

grade OPC. The curing period for PSC is longer compared to OPC, a minimum of 14

days is recommended. The compressive strength of PSC is equivalent to that of

"33" grade OPC. However, slag cements of strength equivalent to

"43" and "53" grade OPC are available in the market. The

slag constituent shall not be less than 25 per cent and not more than 70 per

cent in PSC.

1. Selection of Cement

Selection of

cement is normally based on:

· Durability

Characteristics

·

Functional requirement - Deflection, crack width etc.

· Design

parameters- Strength, fineness, setting time requirement etc.

· Speed of

construction- Time for construction etc.

· Environmental

Conditions- Ground conditions, soluble salts, sulphates, Chemical plants etc.

For normal

building construction like independent houses and villas any of the three type

of cement (OPC, PPC, PSC) can be used. If using OPC, 43 G or 53 G is suitable,

if found economical use 43 G.

The test certificates

indicate:

·

Grade and type of cement

·

Source of cement

·

Week number for which the test certificate is

applicable (week number is printed on each bag of cement.)

·

Test results obtained.

·

Test results required as per Indian Standards.

·

For some test results there may not be

corresponding requirement in Indian Standard. (Like consistency, etc.)

So while

procuring cement, consumers can check the test certificate corresponding to the

batch of cement (week number printed on cement bags) they are buying.

1.

Points to be observed during purchase of cement

On the cement

bag ensure the following:

·

Type of cement – Colour of lettering on the bag

is Black for OPC, Red for PPC and Orange for PSC

·

IS Certification Mark is present.

·

Net mass of cement is marked.

·

Maximum Retail Price (MRP) is indicated.

·

Week number and year of manufacture of the

cement as marked on each bag

·

Check whether the company's original packing is

intact (stitching should be machine stitching only).

·

Check the weight of cement bag. A bag should

weight 50 kg. A variation of ± 0.5kg in any individual bag is permitted as

packing tolerance. However, 20 bags, when weighed together, should not

be less than 1000 kg (net).

2.

Storage of cement

Proper storage

of cement permits easy access for workers. Cement should be stored in suitable

weather-tight structures to protect it from dampness it should be

stored in a manner that no dampness or moisture is allowed to reach it either

from the ground, walls or from the environment. This becomes particularly

important during the humid season and in coastal regions. Cement strength

deteriorates with passage of time by absorbing moisture directly or indirectly.

·

No cement bags should be stacked in contact with

an external wall.

·

Bags should be piled off-the-floor upon wooden

planks. If, however, the floor is a well-constructed dry concrete floor, the

bags can be placed directly on it after spreading tarpaulin or polythene sheet.

·

Cement bags should be placed closely together in

the stack to reduce circulation of air as much as possible.

·

For extra safety during rainy season, the stacks

of cement bags should be enclosed completely in polythene sheets

Cement bags should not be piled higher than

ten bags in a stack and has to be arranged in header and stretcher fashion as

far as possible. While removing the bags for use, the “First in, first out”

rule should be applied.

Cement required

for a day may be stored at site in the open. In such cases cement bags should

be laid on a dry platform made of wooden planks resting over brick-masonry,

concrete, dry sand or aggregates raised about 15 cm above the ground level. The

number of bags should be kept to a minimum, preferably just sufficient for the

day's consumption. The stack must be kept fully covered with tarpaulin or

polythene sheet and protected against atmospheric moisture.

3.

Reason for cement not used in the

neat form

Cement is not

used in neat form because of both technical and economical reasons. Cement

releases considerable quantities of heat during hydration that creates

shrinkage cracks during cooling. This phenomenon causes tensile stresses

resulting in development of cracks in the matrix. Without using aggregate the

matrix form of cement is not effective hence dimensional stability is at stake.

Aggregates such as sand and crushed stone are less expensive than cement.

Mortar is prepared by mixing cement and sand or any other fine aggregate

together with water. Concrete is prepared by mixing cement, sand, coarse aggregate

together with water.

4.

Impact of color on technical

properties of cement

As a general rule there is no impact of

color on technical virtues of cement. Color consciousness is more of a mind set

and conviction, rather than technical performance. As long as the operating

conditions of kiln and the rate of cooling are maintained within the stipulated

limits, cements with any color behave similarly.

5.

Setting time of cement

Setting time of

cement is of practical implication. Basically the initial setting determines

the length of time in which the cement paste remains plastic and workable. The

term setting implies solidification of the plastic cement paste. The beginning

of solidification, called the initial set marks the point in time when the

paste has become unworkable. Accordingly, placement, compaction, and finishing

of concrete beyond this stage will be very difficult. The paste does not

solidify suddenly; it requires considerable time to become fully rigid. The

time taken to solidify completely marks the final set.

6.

Proper cement content in

concrete

Minimum cement

content in concrete is prescribed under BIS code IS: 456 depending upon the

environment to which concrete will be exposed. IS 456 also limits the maximum

cement content in concrete.

It is best to

leave the design of concrete to an experienced civil engineer.

7.

Reasons for slow setting & quick setting of

cement

Slow setting in cement is due to salts and chemicals in

water, sand and aggregate. Cold weather, less cement, high percentage of

impurities, adulterated cement and improper water cement ratio.

Quick setting of

cement is due to addition of low quantity of Gypsum, hot weather condition,

high cement fineness.

contact rabishnair@yahoo.co.in

Subscribe to:

Comments (Atom)